BMA’S HAY POINT BERTH + SHIPLOADER How a model with 2,000+ functional 3D-printed parts “brought project planning to life”

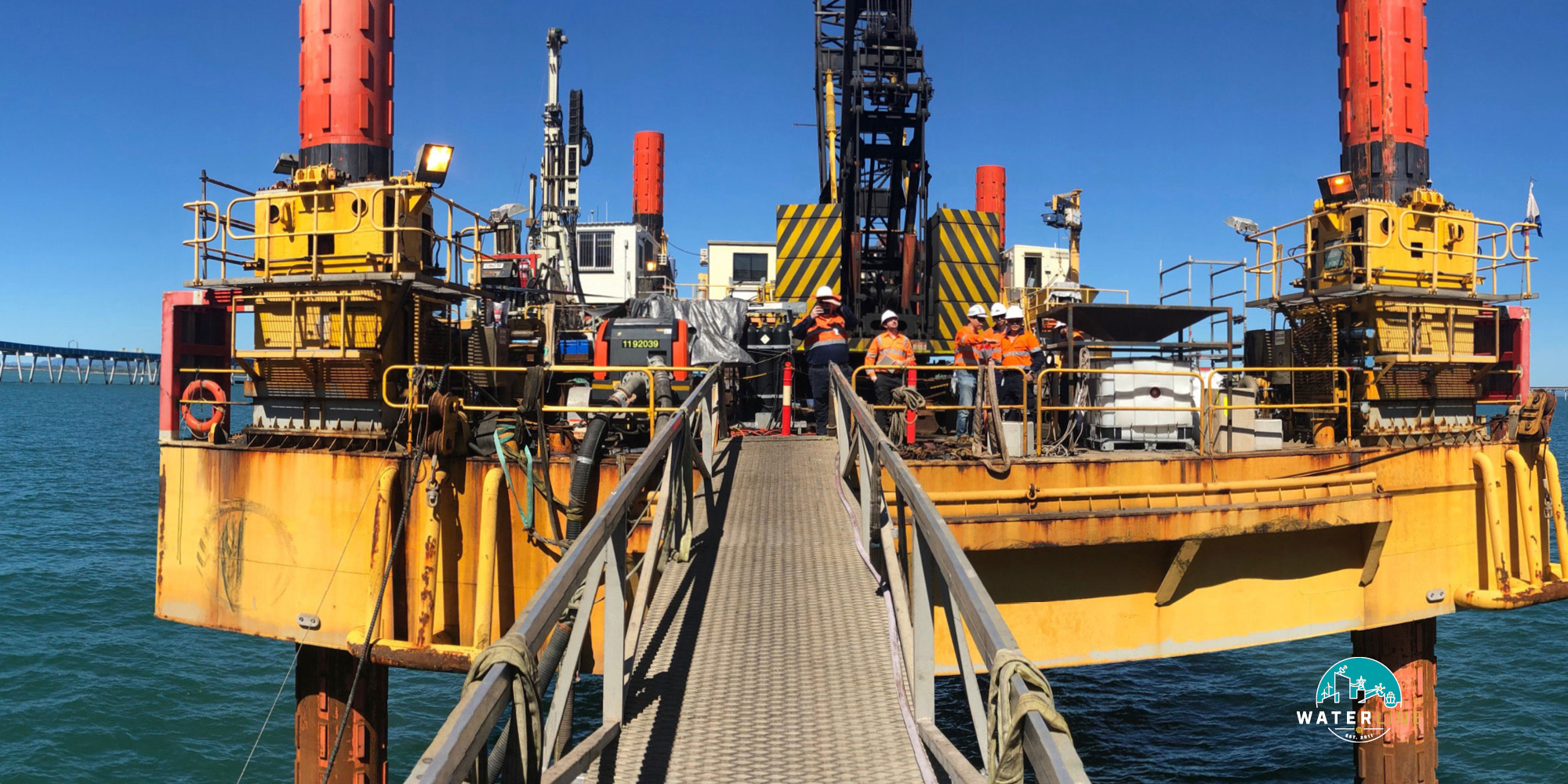

BHP Mitsubishi Alliance’s (BMA) Hay Point Coal Terminal is one of the largest coal export ports in the world. The Hay Point Coal Terminal processes coal from six of BMA’s Central Queensland mines—Goonyella Riverside, Broadmeadow, Daunia, Caval Ridge, Peak Downs, and Saraji.

To improve cyclone immunity and ensure the long-term sustainability of Hay Point Coal Terminal, BMA commenced a maintenance project to replace and upgrade one of the existing shiploaders and berths.

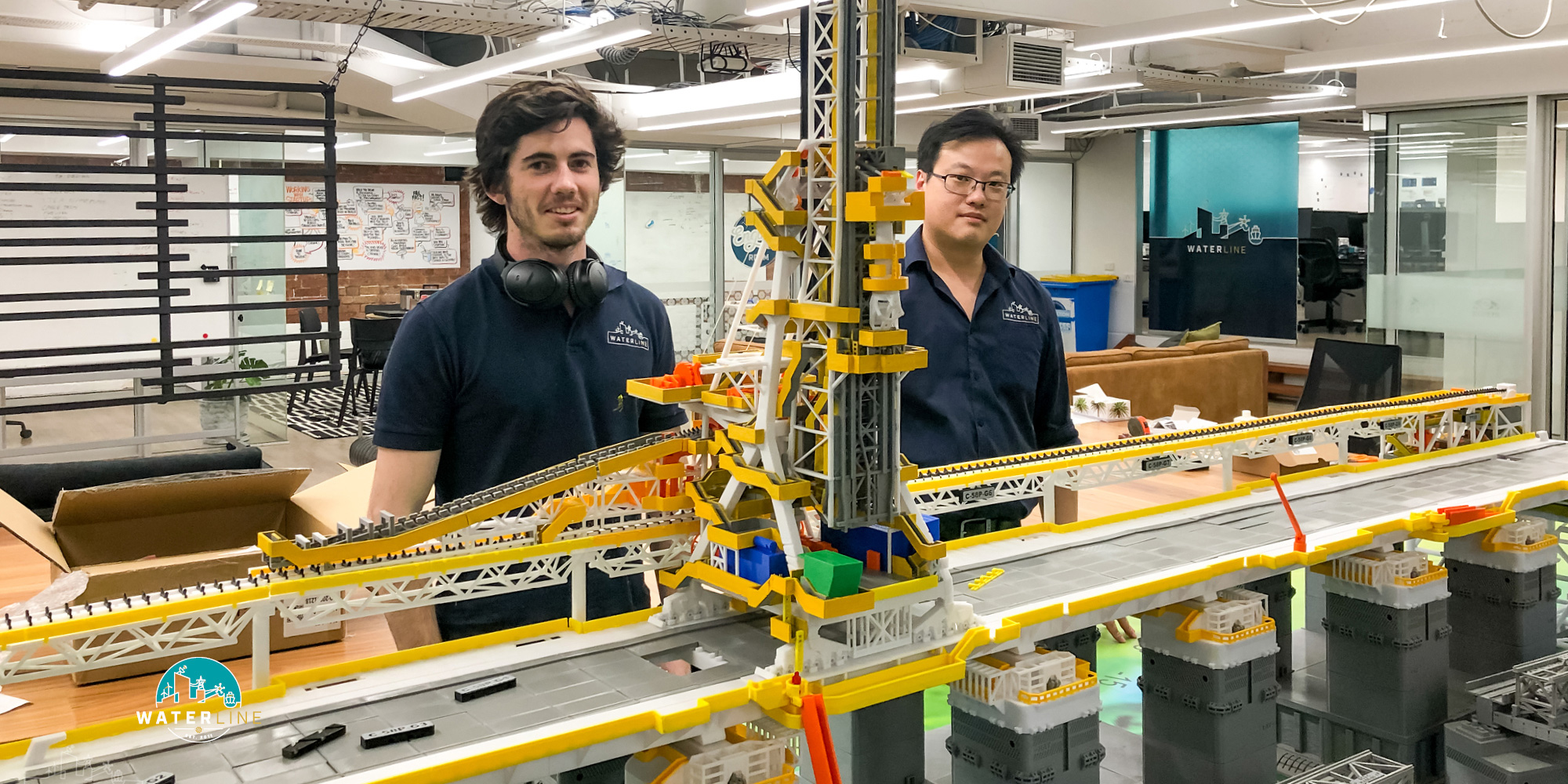

The BMA project team faced the challenge of efficiently and effectively communicating to contracted technical experts the existing structure, connections, and unique berth and shiploader components. The 3D model facilitated a greater understanding of the execution tasks, allowing the project team members to visualise tasks while increasing hazard and risk awareness. Access to a physical model enabled a comprehensive understanding of the scope, as well as the safety focused construction simulations and plans.

Read more about Waterline’s Design + Drafting Services for BMA’s Hay Point Shiploader and Berth Replacement (SABR) Project, and how it helped with collaboration and understanding of the complexities of the project scope.

Every berth and shiploader has unique connection details, components and structural features. This means even highly-experienced technical experts must spend significant time familiarising themselves with a new project to understand the unique challenges arising from its construction.

Proposed plans for disassembly, reconstruction and upgrades must be verified for viability and optimum efficiency.

Traditionally, this means relying on over 500+ existing 2D drawings and 3D modelling. This was making productive collaborative discussions between contractors difficult and time-consuming, especially where challenging concepts could not be effectively explained or easily understood.

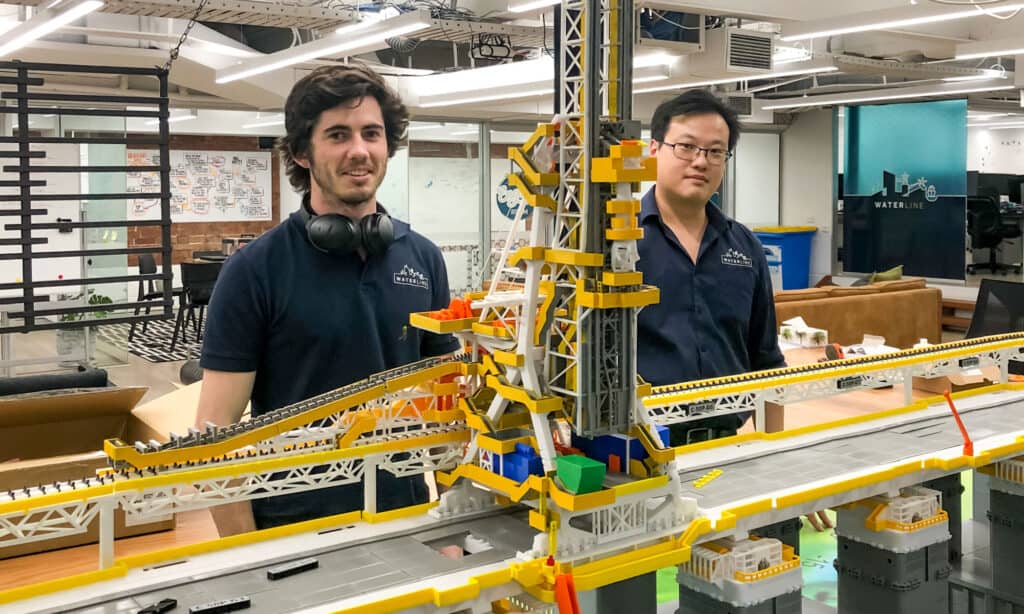

3D-printing a deconstructable model of the existing and proposed new berth and new shiploader. Printed to 1:100 scale and in components labelled with their tonnage, these models allowed the project team to instantly see and understand the hundreds of unique connections and structural components, facilitating productive technical discussions, accurate planning and successful team collaboration.

Having successfully collaborated with Waterline previously (to boost project familiarisation for their dragline fleet), BMA engaged Waterline to see if 3D printing could offer a similar solution for the SABR Project. The scope for the SABR Project was much larger in scale technically and in size.

As operational engineers who provide mechanical, electrical, and operational engineering services at coal export terminals, Waterline understands the specific construction requirements to these large pieces of infrastructure. We were confident we could combine these skills with our technical Design + Drafting services to create functional, fully deconstructable, and technically accurate models of these structures.

The model provided the project team with ‘hands-on’ simulation of the disassembly and installation sequencing, enabling a unique ability to look at the facility as a whole, allowing the project team to identify issues that may not have been foreseen and to quickly understand the project scope, including:

- the relationship between discrete elements

- how to position construction equipment for disassembly

- potential risks with the proposed disassembly methodology

- risks or challenges to personnel safety

- quantities of equipment and their locations

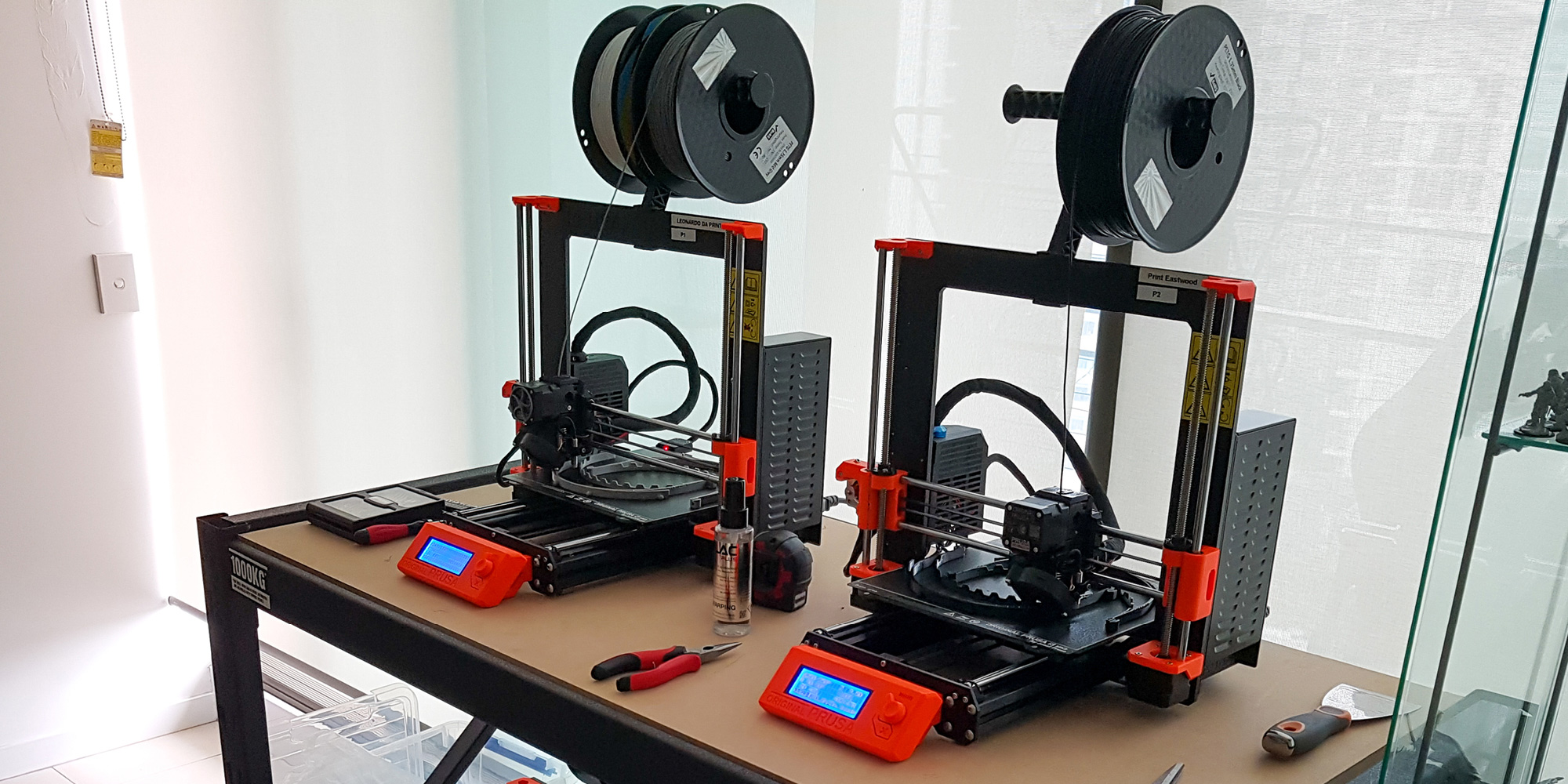

- 1,337 hours of 3D modelling

- 7905 hours of 3D printing

- 804 hours of preparing the 3D-printed parts

- >2000 individually printed 3D parts

- 143 hours to assemble

- Created a 1:100 scale 3D model of the shiploader and berth, 5.2m long, 1m wide and 1m high

The 3D-printed model, which included caissons, top sides, shiploader and ship access ladders, enabled the development of detailed methodologies, policies and procedures, driven by a better understanding of the scope and risks.

Upon delivering the model and watching it in action, Waterline’s CEO, Randall Makin, was impressed with its immediate uptake, commenting,

“What I found to be most profound was the speed at which people learned about the old berth—and the new berth, it was literally minutes until a detailed discussion could happen.”

The model enabled the entire team—from seasoned experts to new graduates, to understand the project scope. This contributed to the successful resolution of engineering challenges, which were fast-tracked due to improvements in understanding the proposed methodologies and potential risks.

Having this model also meant important decisions could be made off site in unforeseen instances, like COVID-19, where site visits may not be permitted, thereby helping to reduce project disruptions.