With extensive structural design and fabrication experience, Visy Glass engaged Waterline to help bring to life Australia’s most sustainable glass furnace in Western Sydney.

Waterline’s Civil & Structural team has collectively more than 120 years of mining and minerals processing experience within senior engineering and drafting personnel.

Our clear and structured processes, coupled with our state-of-the-art analysis software ensures every project is geared for efficiency and optimisation from the very beginning, saving our clients time and money, maximising your return on investment. While working with a team that collaborates with you to deliver mutual success. Our proactive and transparent approach reduces your stress and maintains focus on positive project outcomes—this is why our client engage Waterline for their capital projects.

We treat your projects like our own

Driven to deliver mutual success, our team approaches engineering challenges as if we were the owner. This approach ensures that our solutions are technically robust and realistically implementable, focusing on cost-efficiency, effectiveness and your projects’ long-term viability. This was a main factor in encouraging Visy to work with Waterline, knowing that we would deliver positive outcomes for their business. Afterall, if our clients are successful, our people are also successful.

THE CHALLENGE

Visy is powering the circular economy, closing the loop between packaging, recycling, and remanufacturing.

Committed to delivering sustainable solutions that also benefit the communities in which Visy operates, Visy required a $150 million upgrade of a decommissioned furnace to create Australia’s first oxygen-fuelled furnace for its bottle making and packaging facilities.

THE solution

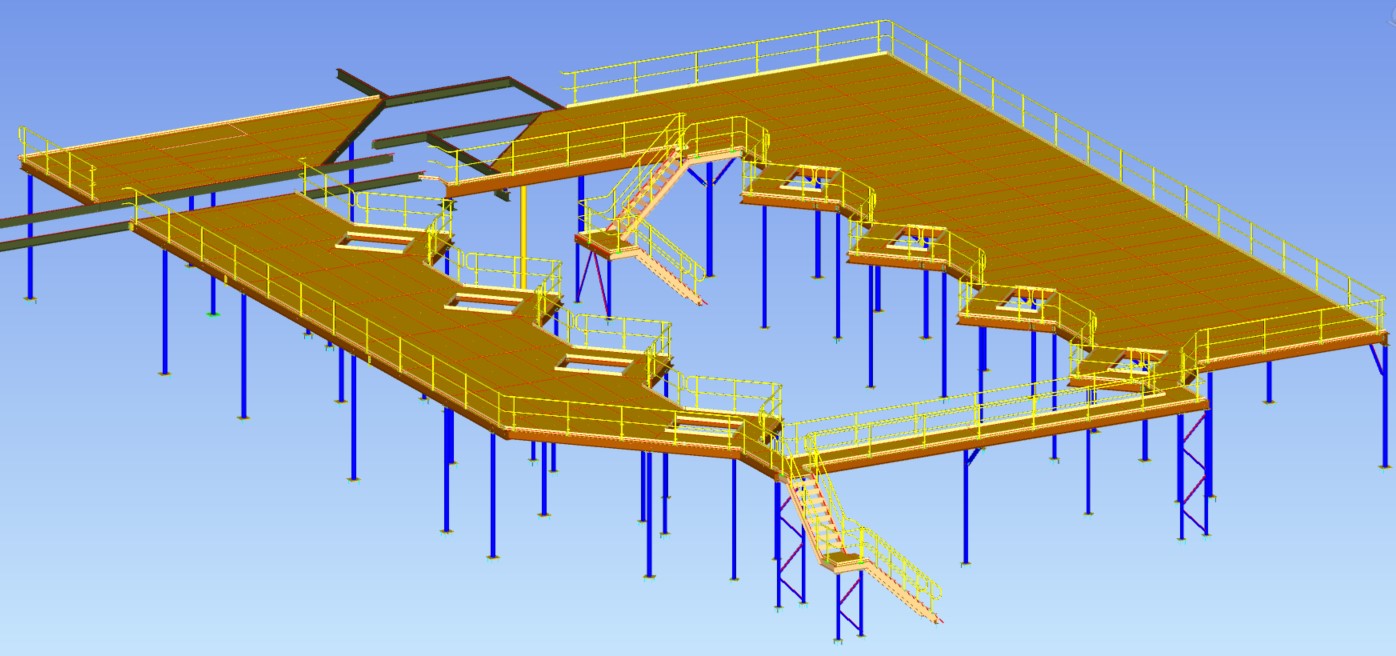

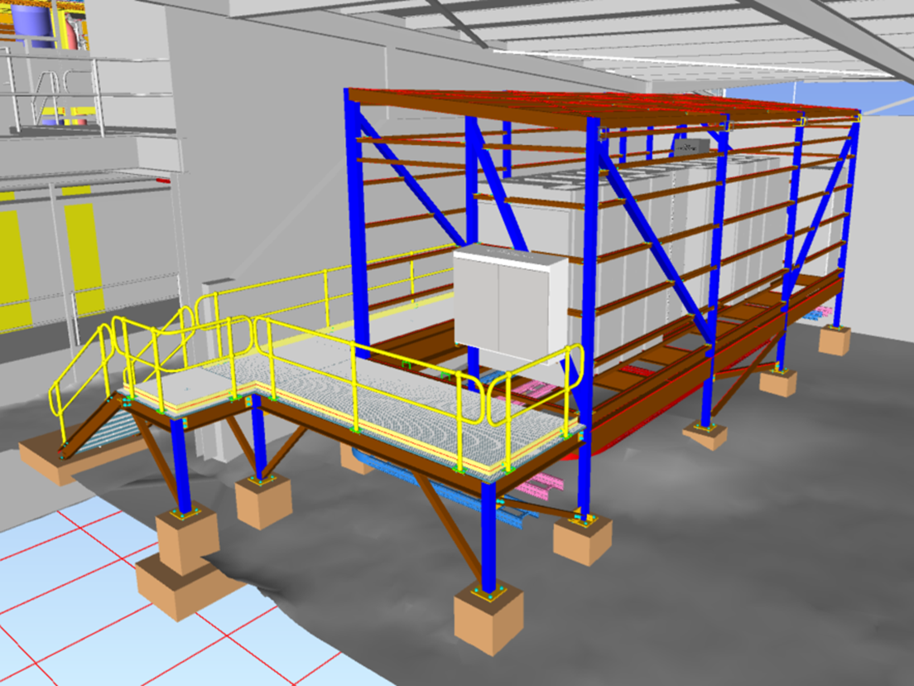

With our extensive structural and fabrication experience, Waterline’s engineers provided structural design and fabrication outputs for several different structural components in different areas of Visy’s plant.

Areas of Work:

- * Cold End Platform (500m2)

- * Forming Machine Access Platforms

- * HV Switch Room

- * Spout Platforms

- * Sampling Access Ways

- * Charge Floor Access Stairs

- Furnace Exhaust Ducting (Mechanical)

- Engineering sign-off for furnace and feed platforms (German designed)

- Deisel Tank Foundations

* Indicates steel fabrication outputs + engineering drawings

THE outcome

With the project now complete, the furnace will be able to produce up to 628 million bottles per year alongside a 45% reduction in energy usage compared to the previous furnace.

Our pragmatic and responsive team delivered on Visy’s requirements and we’re proud to have contributed on the delivery of this innovative and sustainable project. With the high-quality work we’ve produced, the client is engaging Waterline for further support with its other facilities.

Keen to find out how our multi-discipline team can help you deliver on your projects? Contact us now.

Download our case studies eBook to learn more about our proud projects.

“Thanks team Waterline. Fantastic support and super responsive as always!”