Glencore’s Oaky Creek Coal Mine (Oaky) produces some of the most sought-after premium coking coals in the Bowen Basin, exporting to Japan, Asia, Europe, North Africa & South America.

After installing their Gas Drainage Flare Facility (GDFF) to support the coal seam operations, the connecting gas drainage and water pipes needed to cross Oaky Creek in an environmentally acceptable and structurally optimal way. Oaky commissioned Waterline to design, document and manage the implementation of an 84-metre, four-span bridge that would efficiently support both the pipes and limited light vehicle access, while keeping its scale to a practical minimum to limit the capital expenditure. Read how Waterline’s structural engineering team reduced cost of the bridge from 3.5 million to 2.1 million.

High concentrations and volumes of gases within Oaky’s coal seam need to be effectively removed via gas drainage pipes so mining operations can proceed safely, productively and without disruptions.

With creeks in the vicinity, disturbing the creek bed with a buried pipe solution is neither environmentally acceptable, nor technically suitable as water can pool in the pipes and block gas flow.

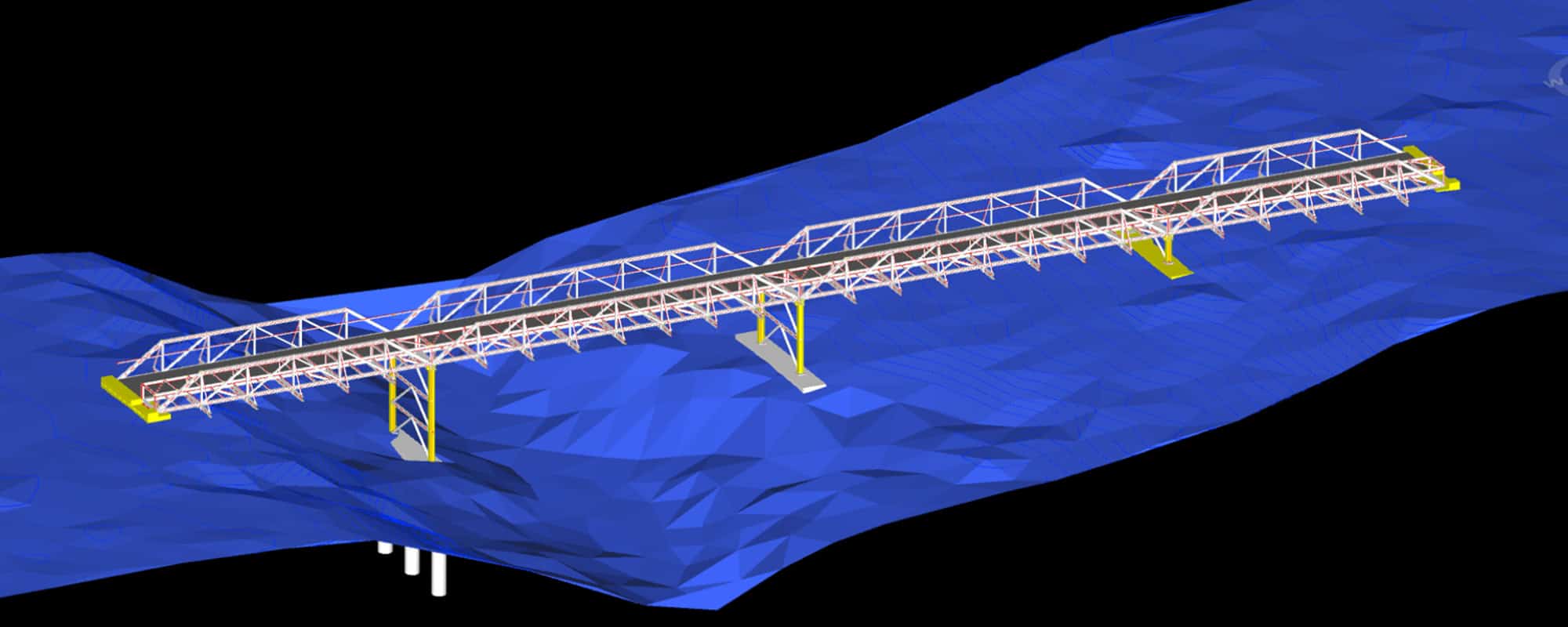

Oaky needed robust access across the creek, that was engineered to not only support their gas drainage infrastructure, but that would reliably withstand a Q100 flooded creek scenario, and provide an alternative route for light vehicles needing to drive across the creek.

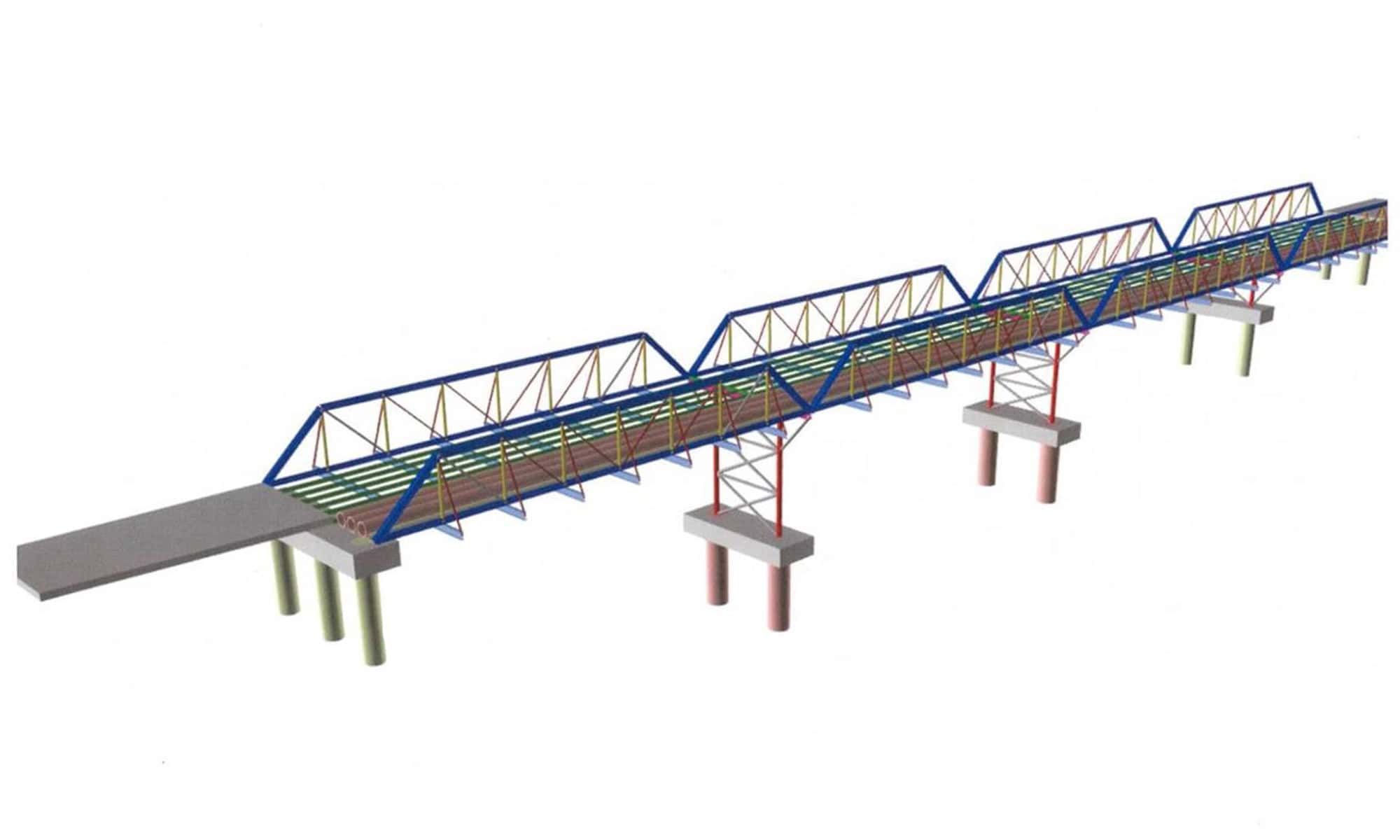

An 84-metre operational and environmentally-compliant bridge across Oaky Creek that housed three 630mm dia. poly gas drainage lines and one 315mm dia. poly water line, while supporting limited light vehicle access in the event of flooding.

Waterline provided this solution via our structural + civil engineering team alongside our cornerstone electrical and mechanical services. Working through the entire lifecycle of a project, our full support and services extend from project management and document control to feasibility analysis and detailed design using state-of-the-art software. We have more than 90 years of cumulative experience in delivering:

Guided by a clear vision and scope from Oaky, Waterline successfully designed and modelled an economical and effective bridge facility that met Oaky’s operational and environmental requirements, while reducing the scale of the bridge superstructure to a practical minimum that effectively achieves the design requirements and limits the capital expenditure.

The design and construction documentation was delivered on time and under the quoted ceiling budget. As we always look to maximise value for our clients and help them make informed decisions about the best way forward, we included three initial bridge concepts for Oaky’s review, along with capital expenditure budget estimates for each option.

The design drawings were completed as smart models, allowing fabrication drawings for the suppliers to be created with ease and helping to reduce fabrication costs. Through downsizing the geometry of the facility, the capital cost of the project was reduced from $3.5 million to $2.1 million.

Our structural engineering and design teams produced 38 deliverables over 642 hours in the detailed design & documentation phase of the project.

John’s knowledge around the design and construction of structures is second to none, he was able to introduce the team to many solutions around problems related to this project specifically. He knows what is required, even when the process followed on mine sites is unconventional and used his industry contacts to assist in the tender process. The design is purpose-built for the environment in which it is to be installed, is professionally approached, and has been utilised for the purposes of completion of a tender and construction and installation.

Discover how Waterline’s solutions can bring precision and expertise to your engineering projects.

Give us a call on 1300 957 111