BHP is the largest coal producer in Australia, responsible for the safe and efficient operation of seven mines across Central Queensland. With personnel safety as a top priority, familiarity with all site equipment is essential for BHP’s ongoing success.

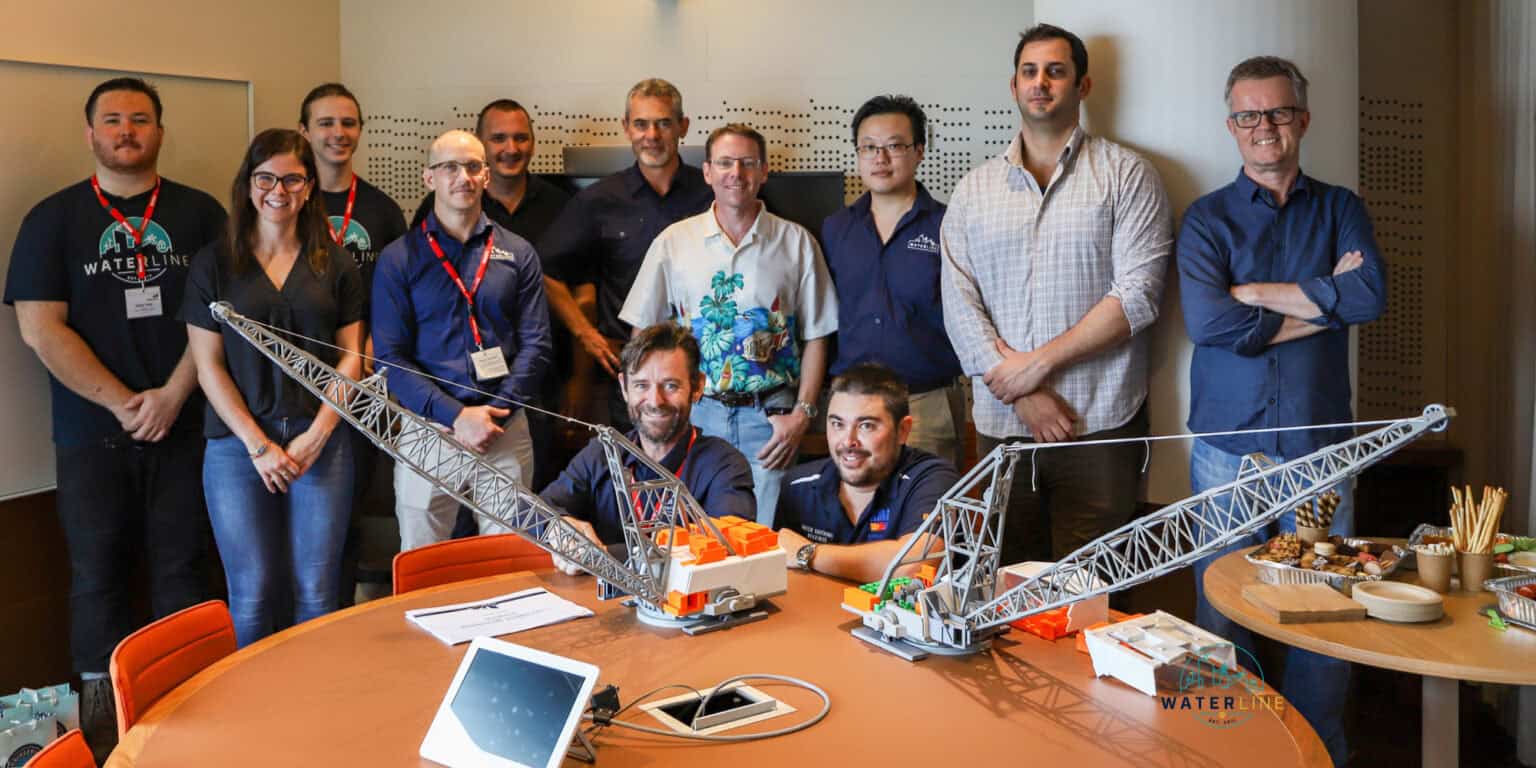

An ongoing challenge for BHP was the unfamiliarity of personnel with dragline function, maintenance and upgrades. BHP partnered with Waterline to use our in-house 3D printing expertise to create fully-functional scale models of draglines that reduced the time taken to become aware of the environment around draglines from weeks to hours – and the increased understanding directly improved safety outcomes.

From 3D model to a 3D-printed tactile conversation piece, the revolving frame section of a dragline printed by Waterline

Personnel who don’t understand the overall operation of a dragline risk exposing themselves to hazards onsite, and adequate familiarisation was taking weeks, coupled with the difficulty of travel – this was impacting BMA’s ability to maintain the machines and keep them running at capacity.

As 3000-tonne machines operating 24/7 to expose coal reserves, draglines are unique to specific kinds of mine sites, leaving many new BMA employees and external trades without context, confidence and underlying knowledge when it came to working with and around these machines. Traditionally, familiarisation includes reviewing 2D drawings, reading manuals and lots of time onsite. Unfortunately, this process was yielding inadequate results for BMA, resulting in difficulties attracting new personnel to the site, sharing the true scope for upcoming projects with external parties, incurring additional expenses in both training and chaperoning staff on the machines, and having their new personnel potentially exposed to hazards that they didn’t appreciate.

Create fully-functional 1:100 scale 3D-printed draglines that enable the BMA team to get hands-on and confident with exactly what to expect – even before they step onsite.

As operational engineers with onsite experience, Waterline knew that looking at drawings did not compare with getting hands-on with the equipment – and even a static model of a dragline wouldn’t attain the best outcomes for BMA. The real benefits would be giving the model realistic functionality and making it fully constructible. We tried both 3D models and virtual reality – but the tactile nature of a 3D model and the ability to just pick it up was the most effective way to communicate that we have used.

Working entirely remotely, Waterline’s design team modelled a Marion 8050 dragline, using our experience with 3D printing and operations to make sure it would be functional at the reduced scale. We used our fleet of six in-house 3D printers to print each of the 82 unique components, ready to be assembled and disassembled in just 15 minutes. The previous hours of hypothetical discussion turned onto minutes of high-quality, tactile conversations that everyone could participate in.

The BMA team could assemble the machinery from the ground-up, raise and lower the boom, understand the hoist, drag and swing functions – and the integration with the electrical drives and motors, plus use the revolving frame to safely plan coordinated access during maintenance activities and major shutdowns.

3D printing scale models enables you to get hands-on with your infrastructure, bulk handling machines, draglines, longwall equipment, wharfs, substations, buildings and any other assets. This allows you to improve training outcomes, better assess project safety, scope proposed design modifications, and make better and more informed business decisions.

Benefits of 3D printing include:

Since receiving the 3D-printed draglines, the time it has taken for a person to become familiar with a dragline-related project has dropped from three weeks to three hours.

To date, everyone who has interacted with one of the models has been blown away. BMA continues to be stoked with the increased safety outcomes onsite, as better familiarisation means less hazards and better-managed risks. Aside from the reduction in familiarisation time, there has been a subsequent cost reduction from minimising the number of site trips for management and project trades to understand dragline functionality and context, as well as effectively plan for shutdowns and maintenance.

Knowledge has not only increased for new employees, but within senior management, too. Waterline have seen 40-year dragline veterans use the 3D model to transfer otherwise complex information to junior staff in 15 minutes. Due to the success of this project, Waterline is now contracted to 3D print other dragline models in BMA’s fleet.