Delta Coal’s Chain Valley Colliery (CVC) produces up to 1.5 million tonnes of thermal coal each year using the Caterpillar EL2000 Shearer. After operating for the past seven years, Delta Coal saw an opportunity to optimise their operations through improvements to the software, hardware and automation of their shearer.

Here’s how Waterline’s remote process control system (PCS) support & automation services have helped Delta Coal obtain a seven per cent improvement in the quality of the coal extracted from a single cut sequence, while improving operational reliability and improving the safety of the operator.

Delta Coal was dissatisfied with the quality and quantity of the coal being extracted by their Shearer and saw an opportunity to reduce their operator’s exposure risk to high dust zones throughout the process.

When you’re committed to working smarter to ensure a safe, reliable and efficient business, as Delta Coal is, having an increased ash content in the coal you extract paired with lower overall production numbers not only impacts your profitability but highlights unmanaged inefficiencies within your operation. Tasking on-site team members with solving this problem would take away from their current duties at the colliery and would not be suitable without the extensive experience necessary in process controls systems & automation to fulfil this task effectively, reliably and in a timely manner.

A site-experienced engineering team that specialises in remote process control systems & automation to solve the problem for you, with minimal disruption to your team & operation.

Having worked almost exclusively in Australian mining for over a decade, Waterline knows the operational pressures faced by sites. When you get the word to increase your operational efficiency and output, you need it done efficiently, reliably, and by a trusted team that completes quality work that generates real, measurable results. You want to ensure that all the boxes are ticked for you – from liaising with the OEM for a comprehensive review of your current software and hardware capabilities, to developing training documentation for your team, to completing every drawing and report to ensure compliance, while successfully installing and automating your software and new systems for ease of use. This is exactly what Waterline provided to Delta Coal.

Our operational engineers ensure your operation is supported 24/7. Optimising your current processes for better operational outcomes, but they will also identify faults, diagnose failures and troubleshoot problems from any location. This means that you protect your site from operational disruptions, reduced efficiency, compliance issues and more.

Software, hardware & automation updates achieve Delta Coal’s desired outcomes from the Shearer’s first shift of operation.

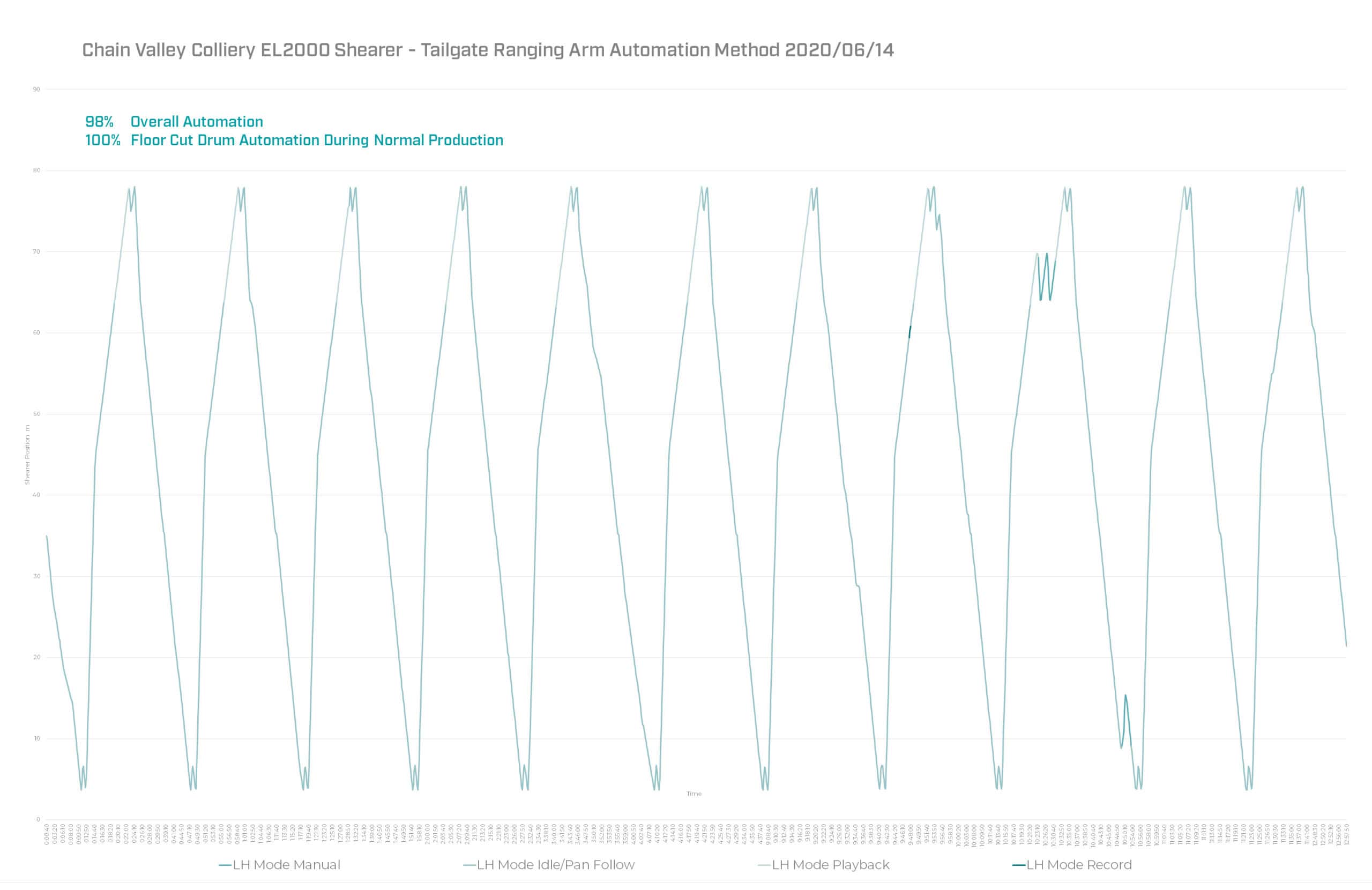

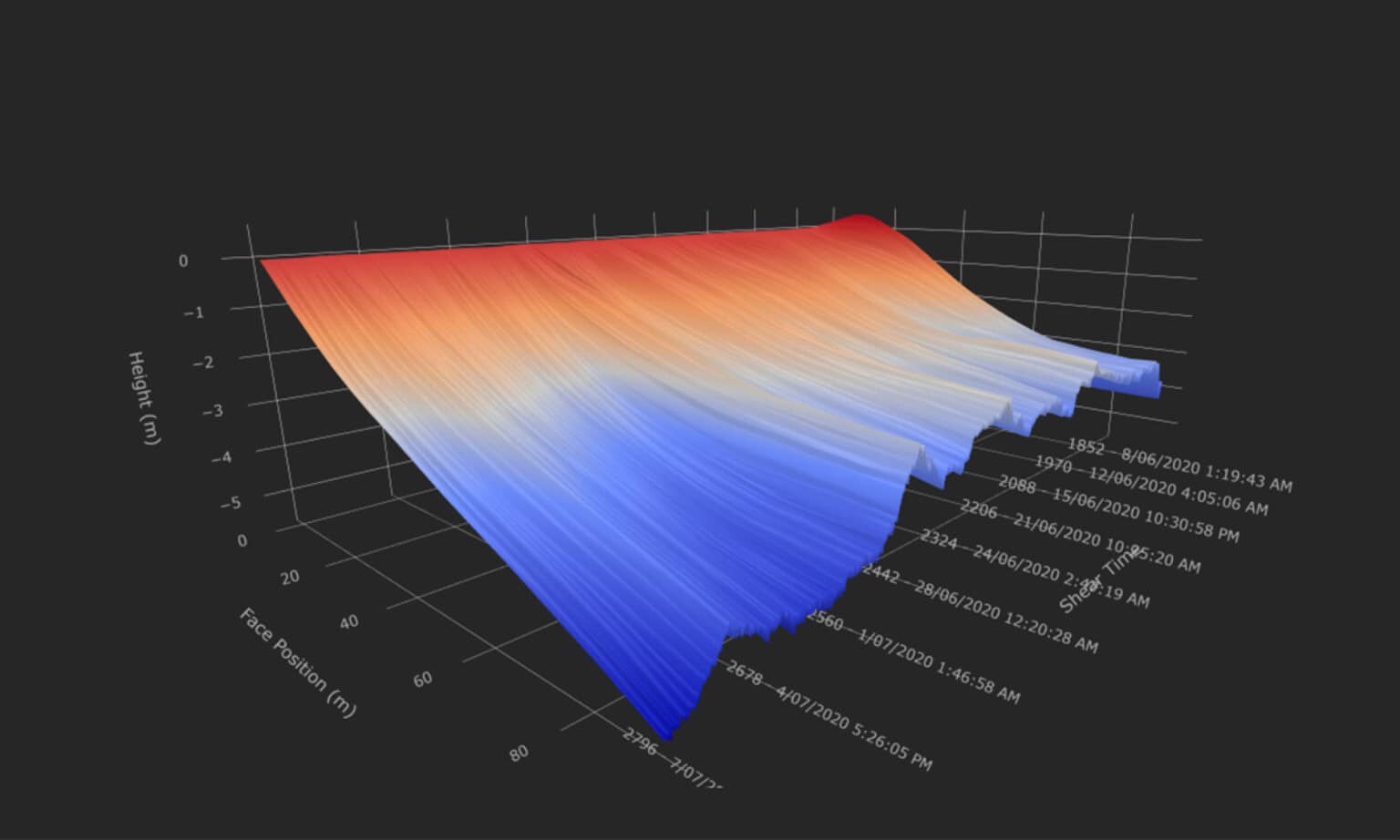

In the first shift after the shearer’s software, hardware and automation updates, Delta Coal immediately saw a 7% decrease in the ash content in their coal. While the Shearer’s production efficiency increased, the operator’s risk of hazardous dust exposure was also minimised as planned. Supported by Waterline’s troubleshooting and technical issue resolution support, as well as the staff training package, the colliery’s operations have remained consistent, reliable and safe.

Waterline worked closely with the Chain Valley engineering staff & operations team to bring this project to a successful completion. Upon review by the Chain Valley Miniwall Superintendent, the team were congratulated on a successful, well-managed and well-implemented change from a manual to automated operation, commenting that the horizon has never been better. We are continuing to work on this project to further optimise CVC’s processes and outcomes.